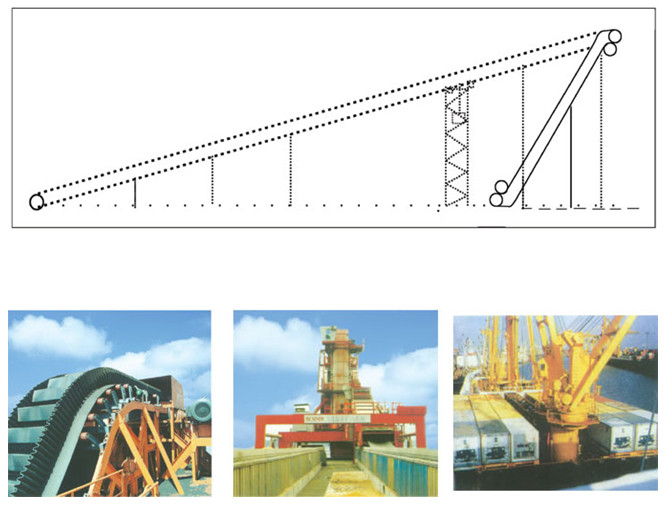

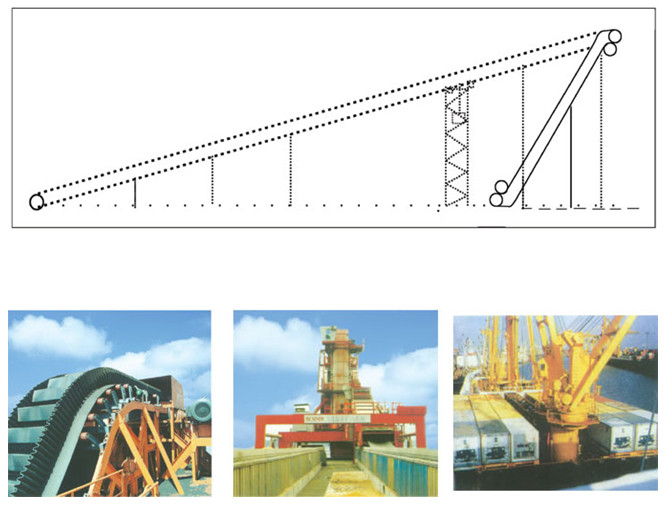

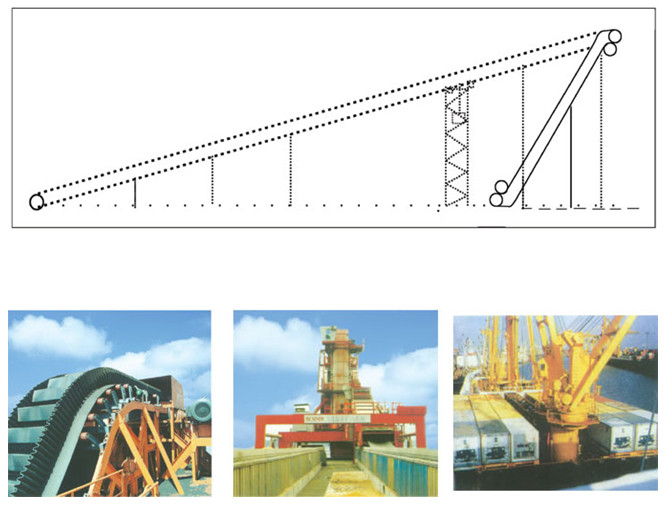

Wavy guard conveyor belt is widely used in ports, metallurgy, mining, electricity, coal, foundry, building materials, food, chemical, etc material transfer. Can make all kinds of bulk material to a 0-90 degrees in any Angle continuous transmission, large transmission Angle, wide use range, cover an area of an area small. No transshipment point, reduce the construction investment and low maintenance cost, etc, bue to solved the common conveyor belt or pattern conveyor belt cannot reach transmission Angle. Wavy guard conveyor belt can be designed into a set of complete conveyor system according to the requirement, to avoid the continuous conveying ascension and complex transportation system. Raised edge conveyor belt wave along the horizontal, inclined and vertical conveying a variety of bulk materials and variable Angle direction, from coal, ore, sand to fertilizers and food, etc.Unlimited, material particle size can be from small size to big size 400 mm, throughput can be from 1 m3 / h to 6000 cubic meters/hour.

Large Angle guard machine Used for dalian beiliang port Export shipment

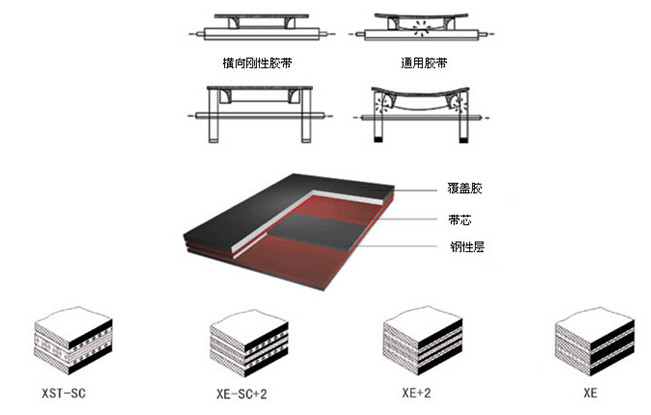

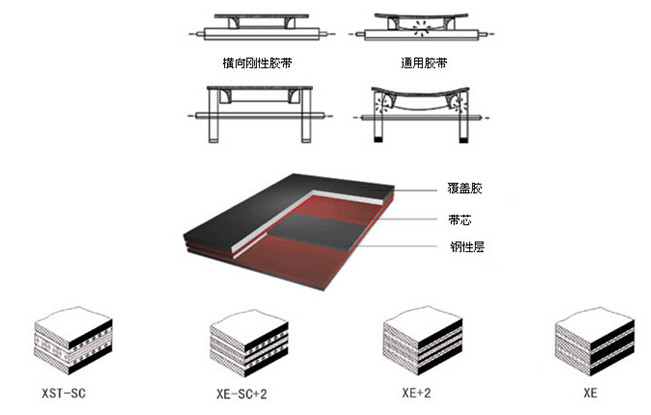

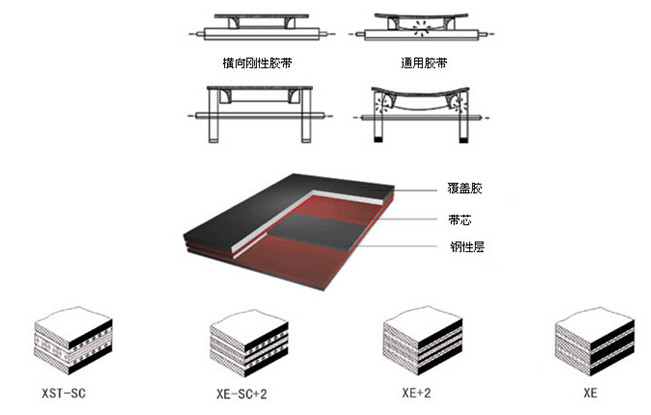

The bandwidth2000mm Rim is high500mm Baseband requirement Raised edge conveyor belt wave with a certain tensile strength and abrasion resistance. The raised edge conveyor belt for free edge of the wave, in order to adapt to the requirement of Angle redirection, vertical requires flexible tape, lateral requires certain rigidity. Company produces the wavy guard conveyor belt adopts special structure lateral rigidity of the baseband, solve the large size belt with collapse phenomenon in the return process. Baseband tectonic baseband is covered in glue, the cover rubber, core and lateral stiffness layer of four parts. Covering the glue thickness is generally 3-6 mm; Under cover the glue thickness 1.5 4.5 mm. Belt core materials under tension, the material can be cotton canvas (CC), nylon (NN), polyester (EP) or canvas rope (ST). In order to increase the lateral stiffness of the baseband in core body join special strengthening layer, called lateral stiffness layer.The width of the baseband specifications, same as the common adhesive tape, comply with the standard GB/T7984-2001.

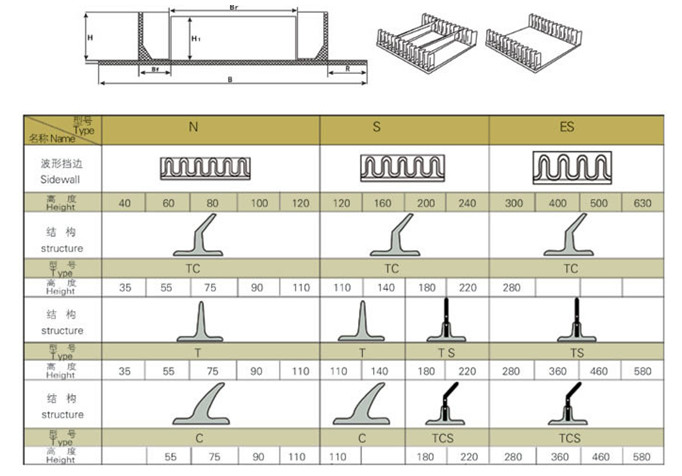

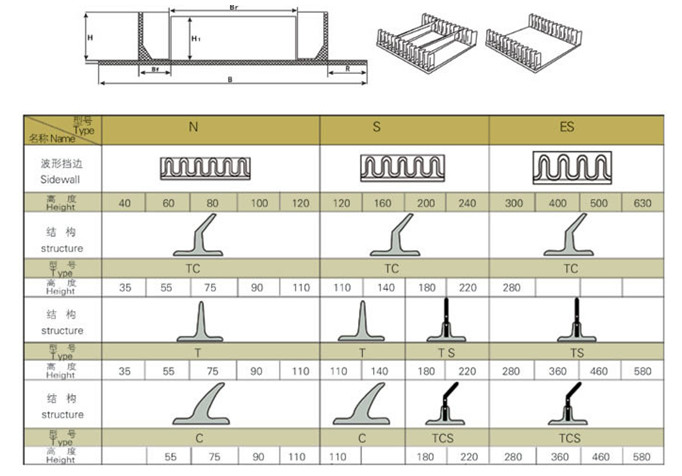

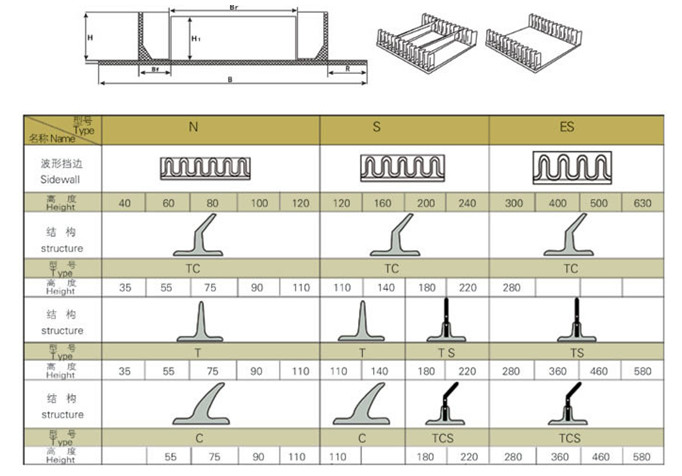

Company according to the principle of wave with the guard wavy guard of the manufacturing process has carried on the reform and innovation, in the wave laceration resistant canvas layer inside the guard post, to enhance wavy guardTear resistance, resistance to flexibility, avoid caused by tensile compression rim torn, increase the service life of the guard.S-shaped wave rim according to carrying capacity can be divided into light (N), medium (S) and heavy (ES). Company production of diaphragm plate made with fiber composite materials, large stiffness, increased resistance to impact, to avoid the diaphragm due to the stress and deformation.In the case of wear heavier, for convenient maintenance, horizontal clapboard can be made cyclopean type, such as TS and TCS. Conveyor Angle less than 40 degrees, transverse diaphragm type T or TS; Angle greater than 40 degrees, the horizontal clapboard, TC or TCS with type C.Decorate the spacing between the horizontal clapboard, consideration should be given and the wave peaks corresponding to the guard. In order to prevent the material from the seam leakage and discharge caused by product material in corner. I company produces the raised edge conveyor belt corrugated, guard, transverse diaphragm and baseband adhesive using secondary low temperature heat vulcanization bonding, high bonding strength, adhesion strong, level off, not to drop, not fall off. Bolted connection between horizontal clapboard and wavy guard, increase the whole rigidity and improve operational performance, material leakage problem is solved. This structure has applied for national patent (patent number: 98222266.1).