DTII type fixed belt conveyor DTII type fixed belt conveyor is universal products can be widely used in metallurgy, mining, coal, ports, power plants, building materials, chemicals, light industry, petroleum and other industries, from stand-alone Or more units to transport the material transport system synthesis, can transport bulk density for the 5000-2500kg, m3 into a variety of bulk materials and items. Bandwidth range (mm): 500 650 800 1000 1200 1400 1600 1800 2000 2200 2400

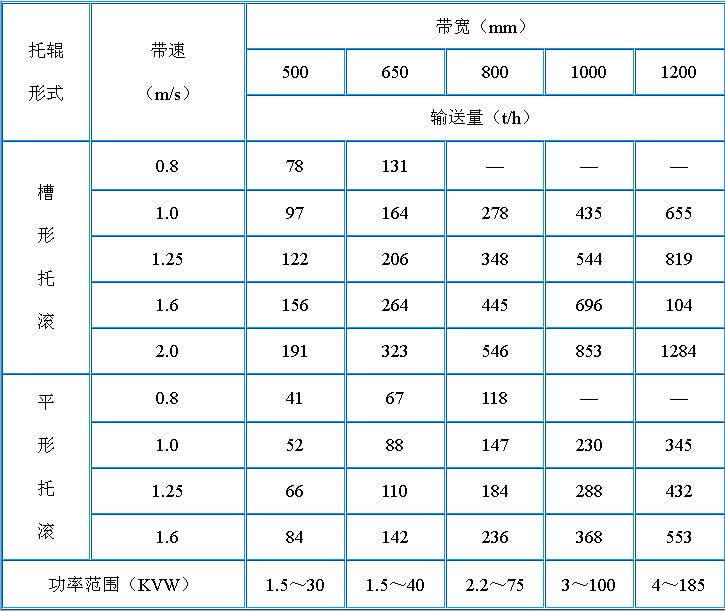

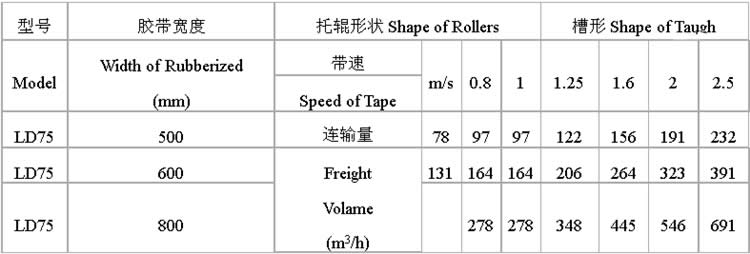

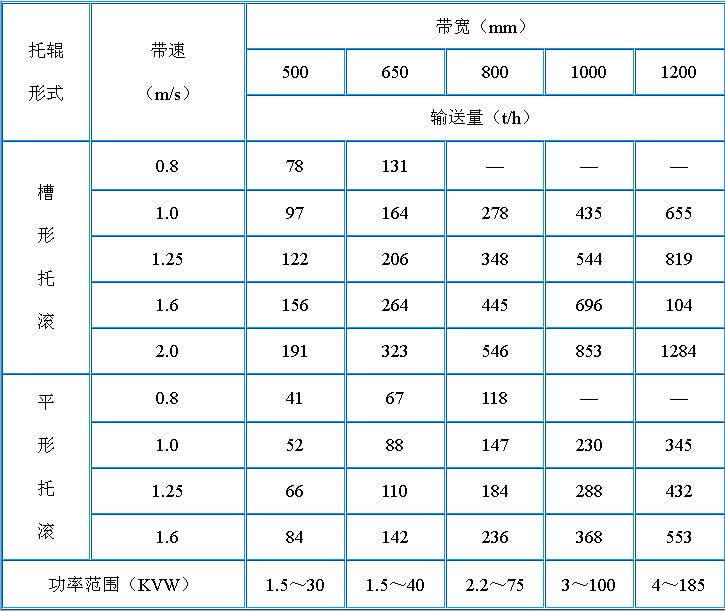

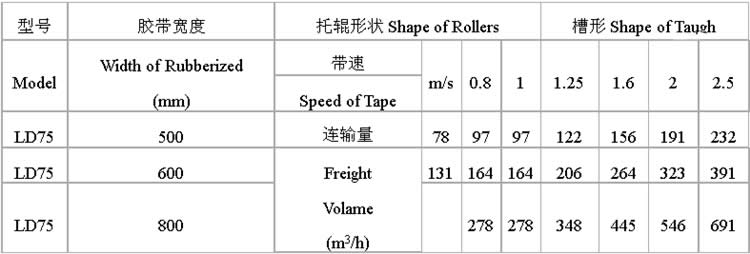

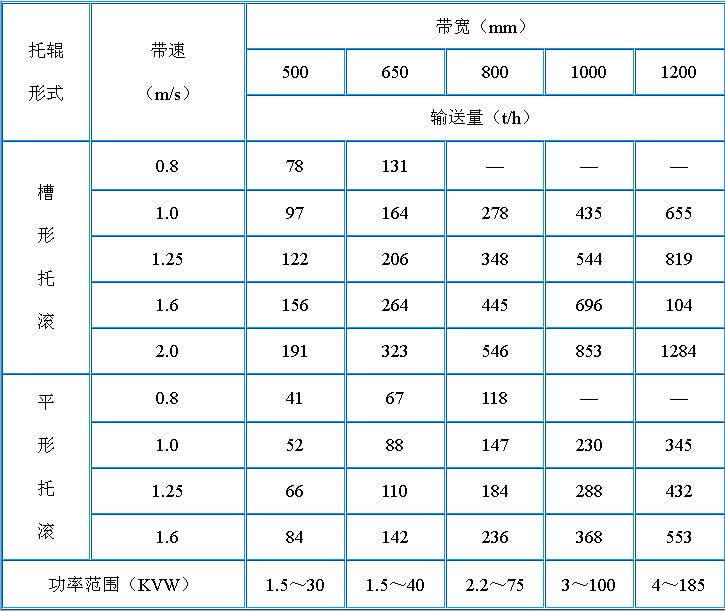

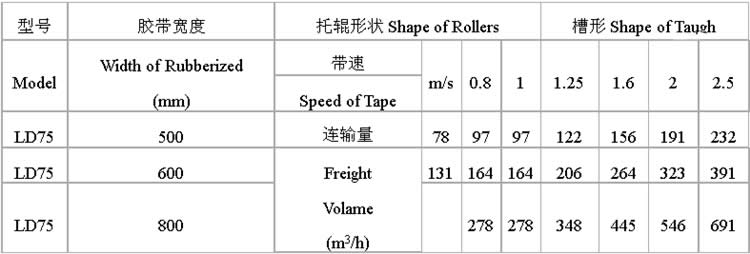

First, use:Widely used in metallurgy, coal, hydropower, transportation and other sectors, transport bulk materials or as items. Requirements under the transmission lines that can separate one, can more than one form or another conveyor system for horizontal or inclined conveyor.Conveyor to the general ambient temperature of 45 ℃ -10 ℃ within the scope of the role, for a dust explosion-proof, corrosion is a requirement need to run the conveyor belt reversible, should the other measures.Second, technical characteristics and main parameters:TD75 type can transport bulk density of 1.0 - 2.5 tons / m 3, a variety of bulk items such as factory production Bandwidth 500,650,880,1000 specifications, the drive power from 1.5KW to 185KW. There 0.8,1.0,1.25,1.65,2.0 belt speed m / s five. The maximum throughput below.

The largest scale transport

Note: The table is in material throughput bulk density: r = 1.0t/m3, conveyor angle 0 - 7 ° material angle of repose of 30 ° moving under the conditions of calculation

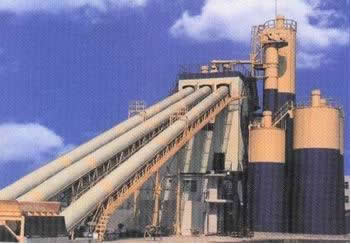

Third, the structure outlined in: Switchboard basic information such as the photo layout. Main structure are: 1, drive parts: by the device in the base of welded steel motor → → → reducer coupling speed reducer shaft component. According to layout requirements: drive with the left and right equipment installed two. In addition, the factory is equipped with power 1.5KW to 185KW, speed 0.80,1.0,1.25 oil cooled electric drum. 2, the rolling part: sub-driving pulley bend pulley and the two categories. 3, roller parts: the sub-groove, parallel, aligning and the buffer roller and so on. 4, cleaning parts: sub-section of the spring cleaner and air cleaner 5, the discharge parts: a fixed plow and unloading points and electric discharge cars. 6, brake parts: a belt and roller backstop backstop the two. 7, Annex: a casing, guide trough, hopper, etc..